The June 1980 issue of Audio Magazine contains an article written by Subir K. Pramanik called “Understanding Tonearms”. This is a must-read tutorial for anyone who is interested in the design and behaviour of radial tonearms.

One of the things Pram talked about in that article concerned the already well-known relationship between tonearm geometry, its mounting position on the turntable, and the tracking error (the angular difference between the tangent to the groove and the cantilever axis – or the rotation of the stylus with respect to the groove). Since the tracking error is partly responsible for distortion of the audio signal, the goal is to minimise it as much as possible. However, without a linear-tracking system (or an infinitely long tonearm), it’s impossible to have a tracking error of 0º across the entire surface of a vinyl record.

One thing that is mentioned in the article is that “Small errors in the mounting distance from the centre of the platter … can make comparatively large differences in angular error” So I thought that I’d do a little math to find out this relationship.

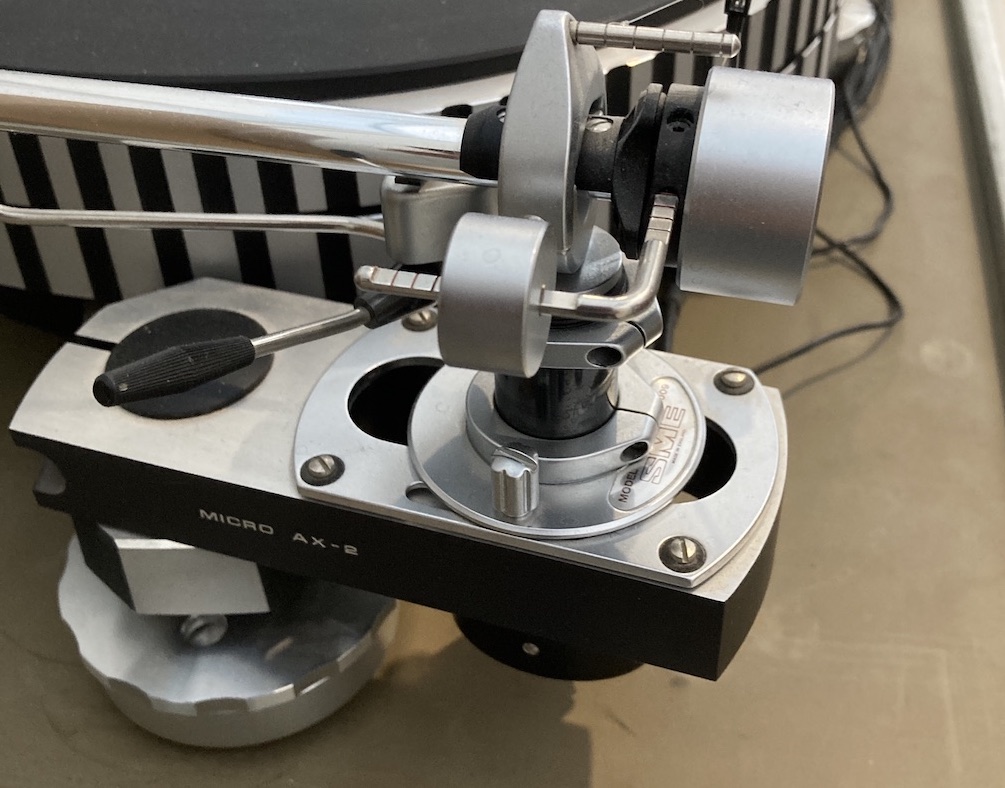

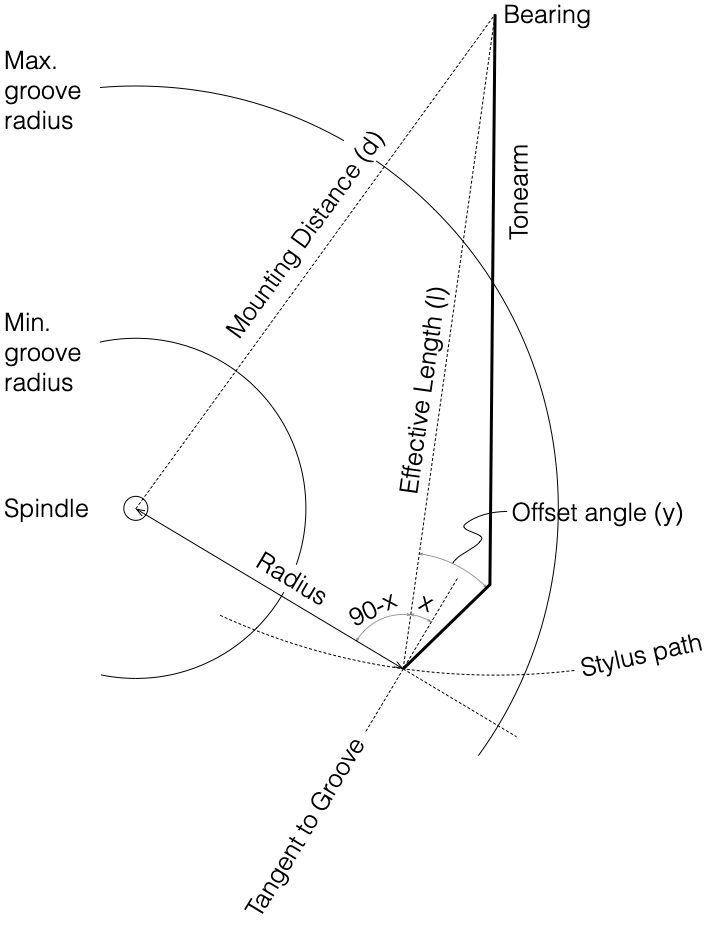

The article contains the diagram shown below, showing the information required to do the calculations we’re interested in. In a high-end turntable, the Mounting Distance (d) can be varied, since the location of the tonearm’s bearing (the location of the pivot point) is adjustable, as can be seen in the photo above of an SME tonearm on a Micro Seiki turntable.

The tonearm’s Effective Length (l) and Offset Angle (y) are decided by the manufacturer (assuming that the pickup cartridge is mounted correctly). The Minimum and Maximum groove radius are set by international standards (I’ve rounded these to 60 mm and 149 mm respectively). The Radius (r) is the distance from the centre of the LP (the spindle) to the stylus at any given moment when playing the record.

In a perfect world, the tracking error would be 0º at all locations on the record (for all values of r from the Maximum to the Minimum groove radii) which would make the cantilever align with the tangent to the groove. However, since the tonearm rotates around the bearing, the tracking error is actually the angle x (in the diagram above) subtracted from the offset angle. “X” can be calculated using the equation:

x = asin ((l2 + r2 – d2) / (2 l r))

So the tracking error is

Tracking Error = y – asin ((l2 + r2 – d2) / (2 l r))

Just as one example, I used the dimensions of a well-known tonearm as follows:

- Effective Length (l) : 233.20 mm

- Mounting Distance (d) : 215.50 mm

- Offset angle (y) : 23.63º

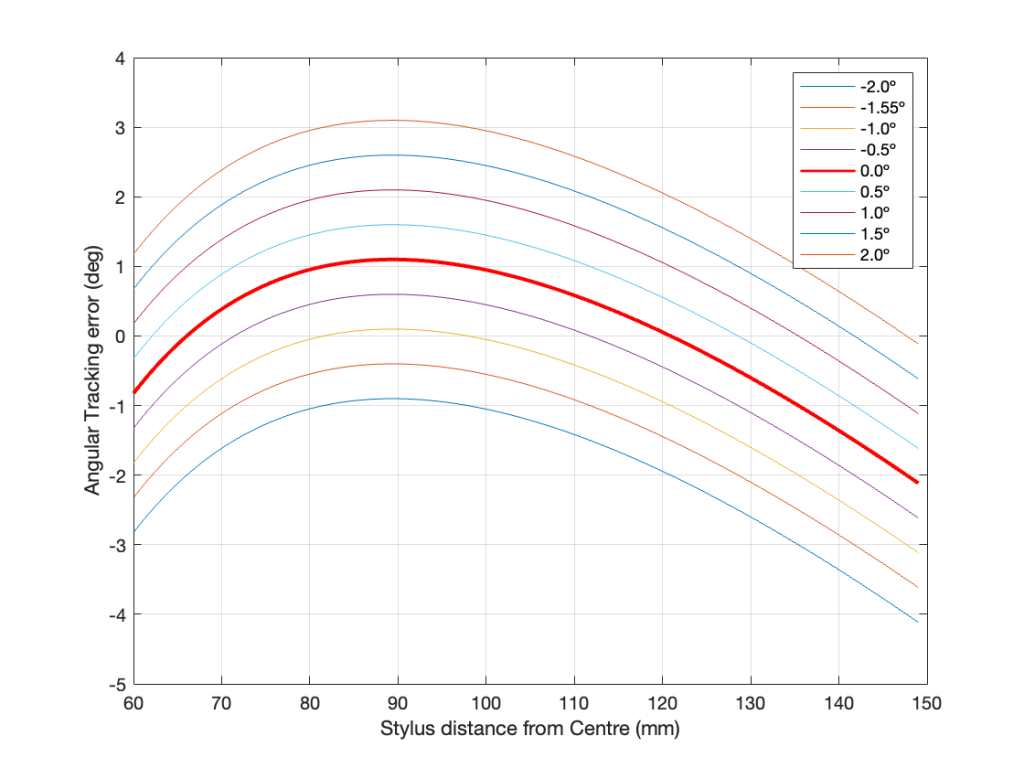

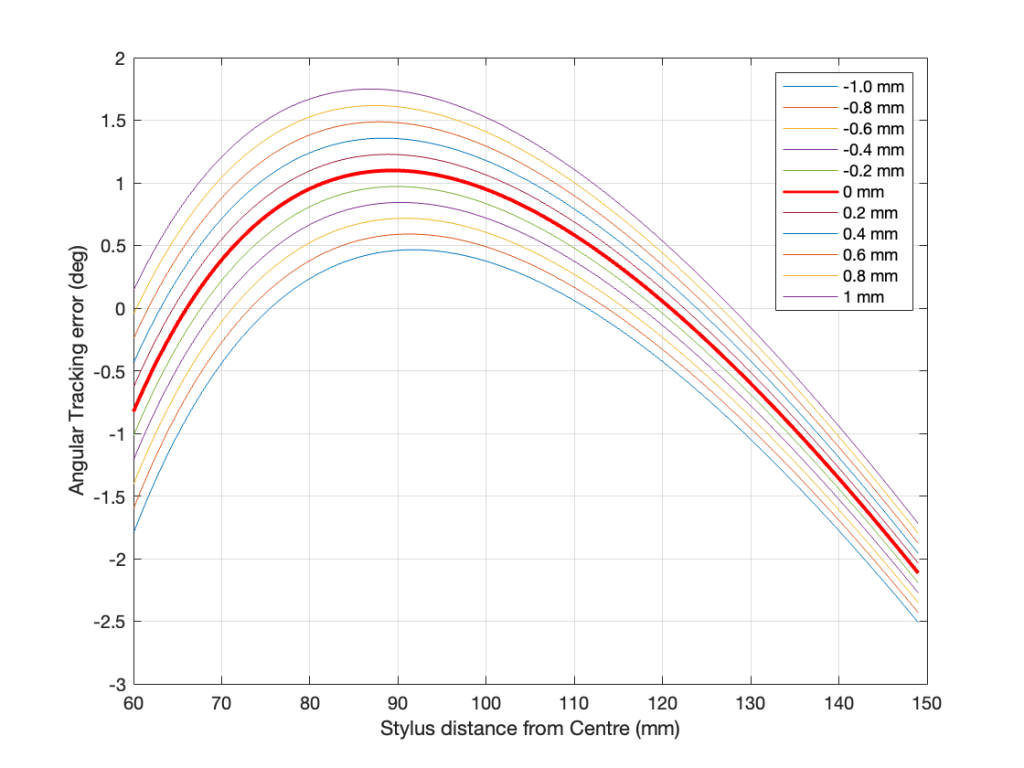

Then the question is, if I make an error in the Mounting Distance, what is the effect on the Tracking Error? The result is below.

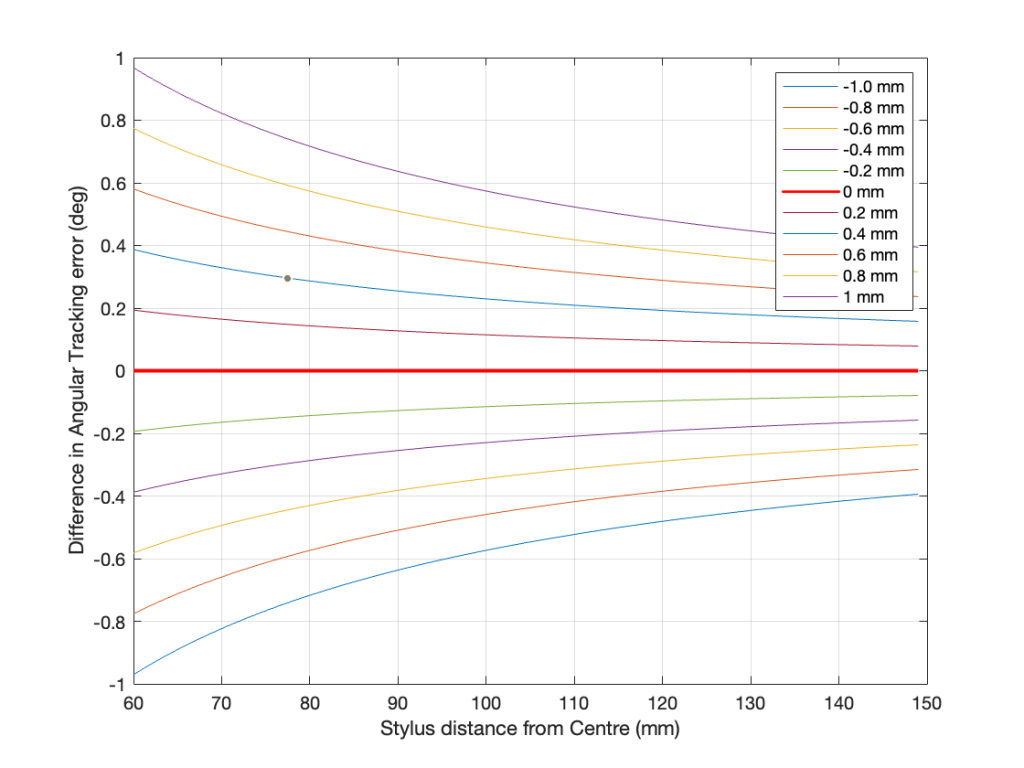

If we take the manufacturer’s recommendation of d = 215.4 mm as the reference, and then look at the change in that Tracking Error by mounting the bearing at the incorrect distance in increments of 0.2 mm, then we get the plot below.

So, as you can see there, a 0.2 mm error in the location of the tonearm bearing (which, in my opinion, is a very small error…) results in a tracking error difference of about 0.2º at the minimum groove radius.

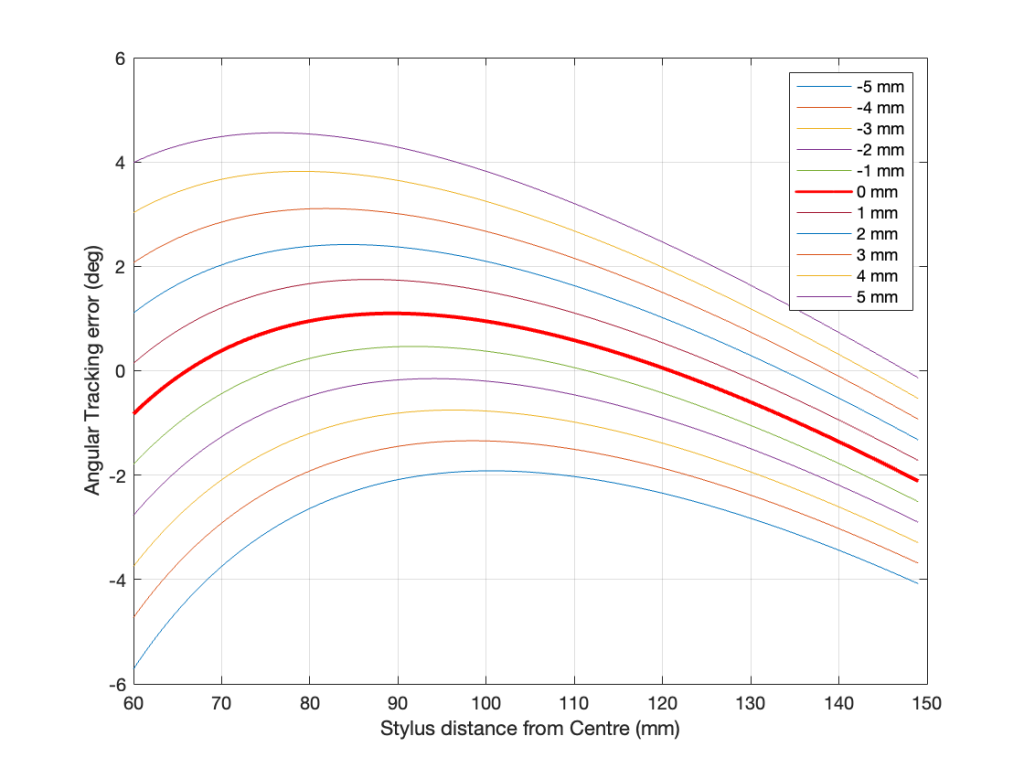

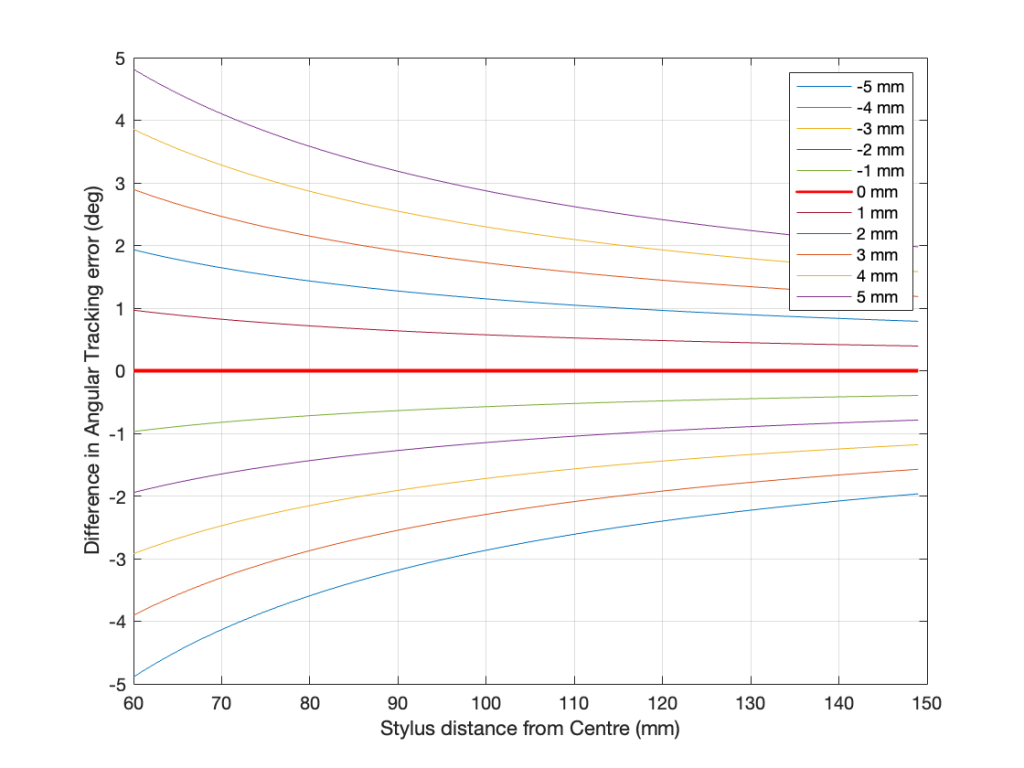

If I increase the error to increments of 1 mm (± 5mm) then we get similar plots, but with correspondingly increased tracking error.

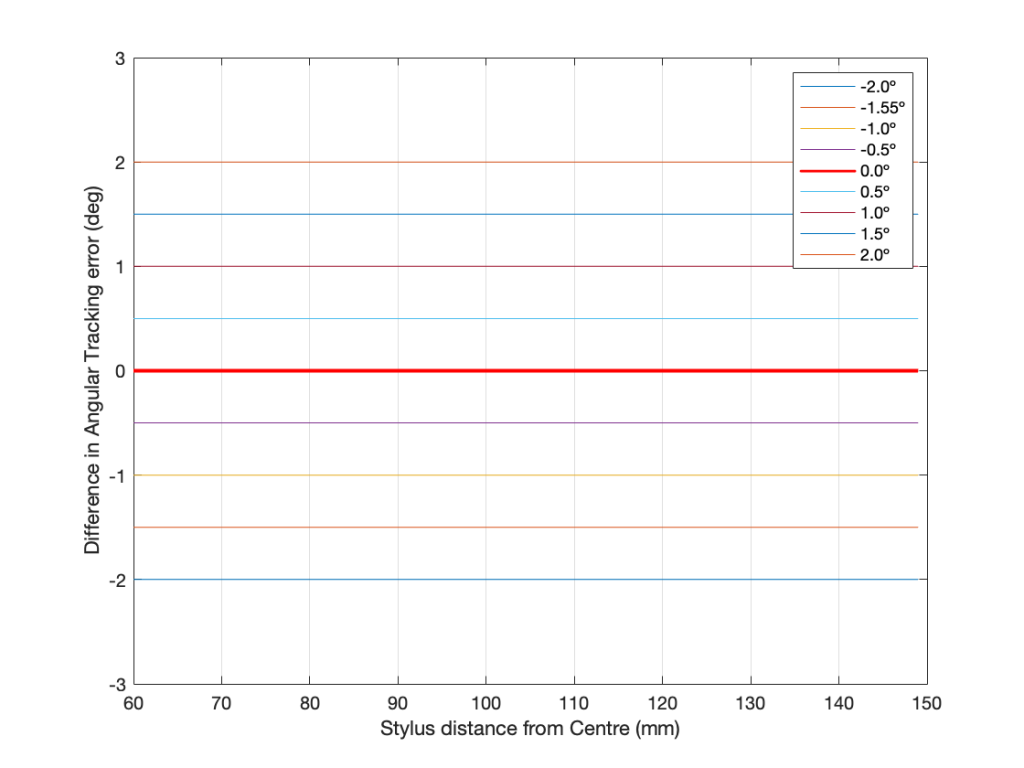

If you go back and take a look at the equation above, you can see that the change in the tracking error is constant with the Offset Angle (unlike its relationship with an error in the location of the tonearm bearing, which results in a tracking error that is NOT constant). This means that if you mount your pickup on the tonearm head shell with a slight error in its angle, then this angular error is added to the tracking error as a constant value, regardless of the location of the stylus on the surface of the vinyl, as shown below.